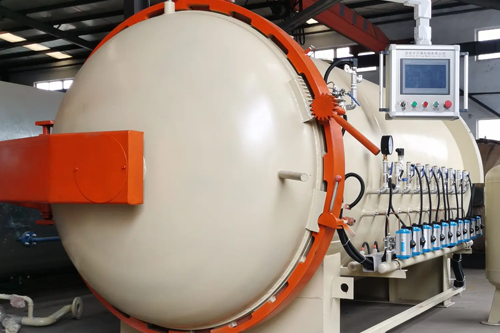

After yarn twisting of polyester or nylon 66 sewing thread, heat set is one important process.

Appropriate perforated dye tube can ensure the dyeing quality of raw white sewing thread and technical twisted yarn, while also enhancing economic efficiency.

How to wind raw white sewing thread & embroidery thread on dye tube, which named precision winding or soft cone winding, is a very important process for further cone dyeing

One summary mark to learn twisting work for filament polyester and nylon sewing threads and technical yarns

Farer updated enterprise resource internal management system to version 2.0. This version 2.0 is fit for filament polyester & nylon yarn twisting process, multifunctional winding and inventory of dyed sewing thread completely.

Trilobal polyester is one basic and advantaged product for Farer to compete in global twisting market.

Farer works with UTS, a professional textile testing center, to perform more complete and deep quality control & research for sewing thread and embroidery thread.

Farer supplies wide bonded nylon 6.6 sewing thread, both raw white on dye tube and lubricated on kingspool.