The dyetubes' functionality and quality deserve attention from twisting manufacturers or dyehouses, this is essential producing high-quality filament high strength polyester sewing thread, embroidery thread and bonded nylon thread.

The uniformity of strength and elongation are two additional core technical indicators, for the twisting of filament thread (typically sewing thread or embroidery thread made from high strength polyester or nylon 66 filaments).

Twist uniformity is a crucial indicator for measuring the twisting quality of filament sewing & embroidery thread manufacturing

A "stable and appropriate speed" is far more capable of ensuring their core strength-elongation performance for high strength filament polyester or nylon 66 sewing thread twisting process.

Spindle fine-management in Farer Thread lays the foundation for producing superior quality filament polyester sewing thread, trilobal embroidery thread, and bonded nylon thread.

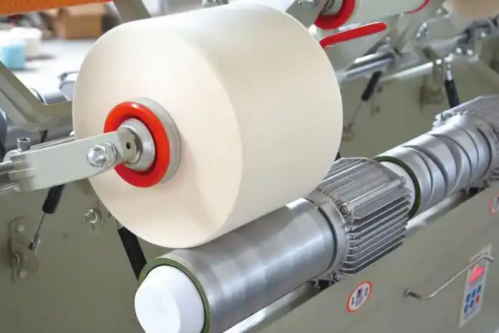

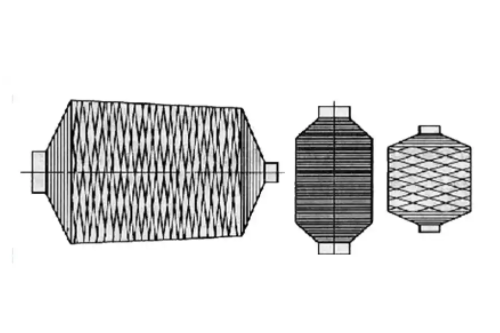

Current Continuous filament high tenacity polyester and nylon 6,6 raw white sewing thread even bonded and embroidery threads in Farer, are all wound on dye tube for package dyeing.

When wind raw white polyester & nylon 66 sewing thread or embroidery thread on dye tube, it is dye package or soft cone, this will be ready to dye.

Dye package precision winding of twisted filament polyester and nylon 6.6 high tenacity thread, also called soft cone winding, is one important step bringing raw white twisted yarn or thread to dye tube, for further dyeing.